In the world of meat processing, keeping the animal carcass clean and of top-notch quality is absolutely vital. One game-changing piece of equipment that makes a huge difference? The dehairing machine! If you're in the slaughterhouse biz, particularly in places like Canada, having a dehairing machine isn’t just a luxury; it’s a must-have for meeting those high hygiene and quality standards.

In this step-by-step guide, we’ll walk you through how to operate a dehairing machine, the benefits it brings to your operations, and the key factors to consider when choosing the perfect machine for your facility. Whether you're in Brampton or anywhere else, teaming up with the right dehairing machine supplier is essential for keeping your operations efficient and safe.

1. What’s a Dehairing Machine, Anyway?

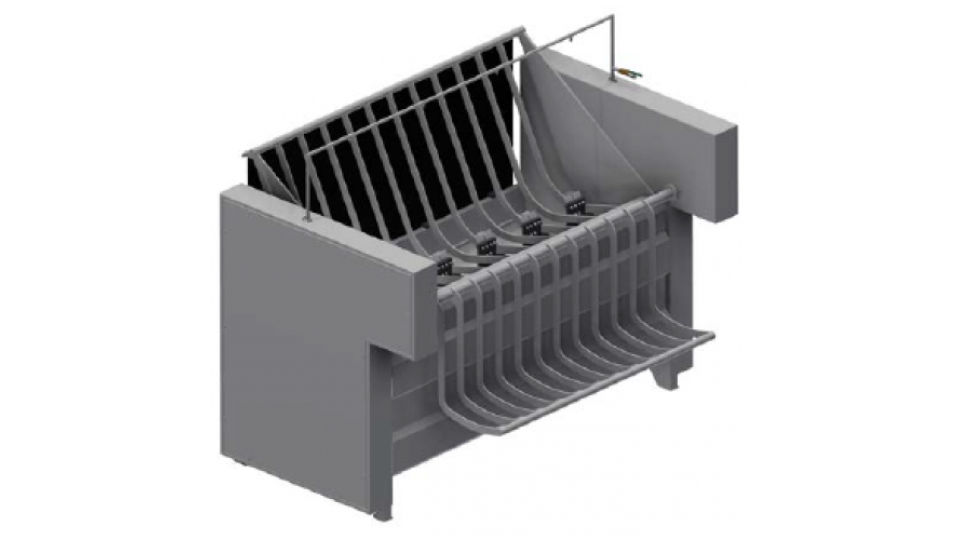

A dehairing machine is an essential tool in the meat processing industry, designed to efficiently remove hair, bristles, or feathers from animal carcasses after slaughter. While it’s most commonly associated with pig processing, this versatile machine can be adapted for use with other animals like poultry and cattle. It transforms what would typically be a time-consuming, labor-intensive task into a streamlined process, ensuring that carcasses are thoroughly cleaned before moving on to the next stages of meat processing.

In Canada, especially in bustling regions like Brampton, having a top-notch dehairing machine is crucial for slaughterhouses and meat processing facilities striving to meet rigorous food safety standards. Teaming up with a trustworthy dehairing machine supplier means you’ll find the right fit for your facility, paving the way for smooth and efficient operations!

1. Why Use a Dehairing Machine?

Using a dehairing machine comes with a host of benefits that can elevate your meat processing operation:

a. Efficiency and Speed

Let’s face it—time is money! One of the biggest perks of a dehairing machine is how quickly and efficiently it gets the job done. Instead of spending ages scraping hair off carcasses by hand, this machine automates the process, saving you precious time on each one.

b. Improved Hygiene

Who wants hair, dirt, or other contaminants in their meat? A dehairing machine ensures that every carcass is free from unwanted bits, not just for looks but also to uphold those crucial hygiene standards in meat processing.

c. Labor Reduction

With a dehairing machine on your side, you can significantly cut down on manual labor. This means lower labor costs and less physical strain on your workers, letting your processing line operate more smoothly and efficiently.

d. Consistency

Say goodbye to the guesswork! A dehairing machine delivers consistent results, making sure each carcass receives the same treatment. That kind of reliability is hard to come by when relying on manual methods, which can often lead to uneven hair removal.

e. Compliance with Health Regulations

In Canada, adhering to strict health and safety regulations is non-negotiable for meat processing facilities. A dehairing machine helps you stay on the right side of those standards, ensuring that you provide safe, clean, and high-quality meat to your customers.

2. Step-by-Step Guide to Operating a Dehairing Machine

Now that we’ve covered the benefits, let’s go over the step-by-step process for operating a dehairing machine in your facility.

Step 1: Prepare the Carcass

Before placing the carcass into the dehairing machine, it needs to be properly prepared. In most cases, the animal is first scalded in hot water to loosen the hair. This step is essential for making the dehairing process more efficient.

-

Scalding temperature: The water should typically be heated to around 58-62°C (136-143°F) for pigs. Make sure the temperature is within this range to avoid damaging the carcass or making the hair removal process harder.

-

Scalding time: The carcass should remain in the hot water for around 4 to 6 minutes. Monitor the process closely, as over-scalding can cause the skin to tear.

Step 2: Get That Carcass Ready for the Dehairing Machine!

Once you’ve finished scalding, it’s time to move on to the next step: transferring the carcass to the dehairing machine. Depending on your setup, this might mean placing the carcass on a conveyor belt, securing it to a rotating drum, or even manually feeding it into the machine.

Safety First!

Before you dive in, make sure the machine is turned off! Always stick to safety protocols to keep things accident-free and protect yourself during this process.

Step 3: Activate the Machine

With the carcass in place, it’s time to activate the dehairing machine. Most machines come equipped with controls that allow you to adjust settings such as speed and pressure to suit different animal sizes and hair types.

-

Speed settings: Adjust the speed according to the thickness of the animal’s hair. For pigs with thicker bristles, a higher speed may be necessary, whereas lighter settings are suitable for poultry.

-

Monitoring the process: Watch the machine as it operates to ensure that hair is being removed efficiently. Depending on the machine's design, rotating blades, rollers, or paddles will work to scrape the hair off the carcass.

Step 4: Check and Reposition the Carcass

After the initial dehairing cycle wraps up, it’s time to hit pause on the machine and take a good look at the carcass. Sometimes, those pesky hairs like to hide in hard-to-reach spots. If you spot any stubborn patches, don’t hesitate to reposition the carcass for another round of dehairing or tackle those stray hairs manually with a scraper.

Key Areas to Check:

Keep an eye on tricky spots like the ears, snout, and feet—these are often where hair likes to hang out and can be a bit more stubborn to remove.

Step 5: Rinse and Sanitize the Carcass

After the dehairing process is complete, the carcass should be thoroughly rinsed with clean water to remove any remaining hair, bristles, or debris. This step is crucial for hygiene and prepares the carcass for the next stages of processing.

-

Sanitizing the carcass: Depending on your facility’s protocols, a sanitizing solution may be used to ensure that no bacteria or contaminants remain on the carcass post-dehairing.

Step 6: Clean the Dehairing Machine

Proper maintenance and cleaning of the dehairing machine after each use are essential to ensure its longevity and hygiene. Meat, hair, and debris can accumulate in the machine during operation, and if left unchecked, this can lead to contamination or mechanical issues.

-

Turn off the machine: Always disconnect the power source before beginning any cleaning process to prevent accidents.

-

Remove parts for cleaning: Depending on your machine’s design, you may need to remove certain parts such as paddles, drums, or rollers for thorough cleaning.

-

Sanitization: Use food-grade cleaning solutions to sanitize the machine after cleaning. This will help ensure that the machine is ready for safe operation during the next production cycle.

3. Finding the Perfect Dehairing Machine for Your Facility: Let’s Get It Right!

Choosing the right dehairing machine is key to boosting efficiency and ensuring your meat processing is top-notch. Here are some important things to think about when picking a machine for your facility:

a. Capacity and Throughput

First things first: what’s the size of your operation? If you’re running a cozy little setup, you won’t need a giant machine taking up all your space. But if you’re in a larger operation, especially in bustling areas like Brampton or other parts of Canada, you’ll want a high-capacity machine that can keep up with your production needs without breaking a sweat.

b. Machine Type

Not all dehairing machines are one-size-fits-all! Some are specifically designed for pigs, while others cater to poultry. Make sure you choose a machine that’s tailored to the type of carcass you’ll be processing most often. You wouldn’t want to wrestle with a machine that’s not up for the job!

c. Durability and Build Quality

You need a machine that’s built to last! Look for one made from tough materials like stainless steel that resist rust and corrosion. This is super important in environments where machines will get splashed with water, cleaning agents, and meat products. A reliable dehairing machine supplier can help you find equipment that’s sturdy and ready to take on the daily grind.

Remember, the right dehairing machine is like finding the perfect partner for your facility—make sure it meets your needs and can keep things running smoothly!

d. Supplier Support

When investing in a dehairing machine, it’s essential to partner with a reliable Dehairing Machine Supplier who can offer support, maintenance services, and replacement parts. For businesses in Canada, working with local suppliers in regions like Brampton can ensure you get timely service and support when you need it.

Conclusion

Using a dehairing machine correctly is crucial for upholding top-notch hygiene standards and ensuring smooth meat processing. By following the step-by-step guide above, you can maximize the performance of your dehairing machine, boosting productivity and enhancing product quality in your facility.

But it's not just about operation! Regular maintenance and thorough cleaning are essential to keep your machine running smoothly, prevent unexpected breakdowns, and comply with health and safety regulations. Partnering with a trusted dehairing machine supplier ensures you get the right equipment tailored to your needs, so your operations in Canada or Brampton can thrive without a hitch!

For more information on high-quality dehairing machines, visit Presto Precision Plus, your trusted source for industrial equipment that enhances efficiency and product quality.