Meat processing industry, efficiency and hygiene are two critical factors that play a vital role in ensuring high-quality production. One piece of equipment that significantly impacts both of these aspects is the dehairing machine. Dehairing machines are designed to remove hair from animals, primarily pigs, in a fast and efficient manner, reducing manual labor and ensuring a cleaner and more hygienic product.

In this comprehensive guide, we’ll explore everything you need to know about dehairing machines, including their importance in the meat processing industry, the benefits of using them, and how they work. We will also touch on specialized machines like the dehairing machine for sows, and discuss the availability of dehairing machines in Canada. Let’s dive in and understand why these machines are an essential part of modern meat processing.

What Are Dehairing Machines?

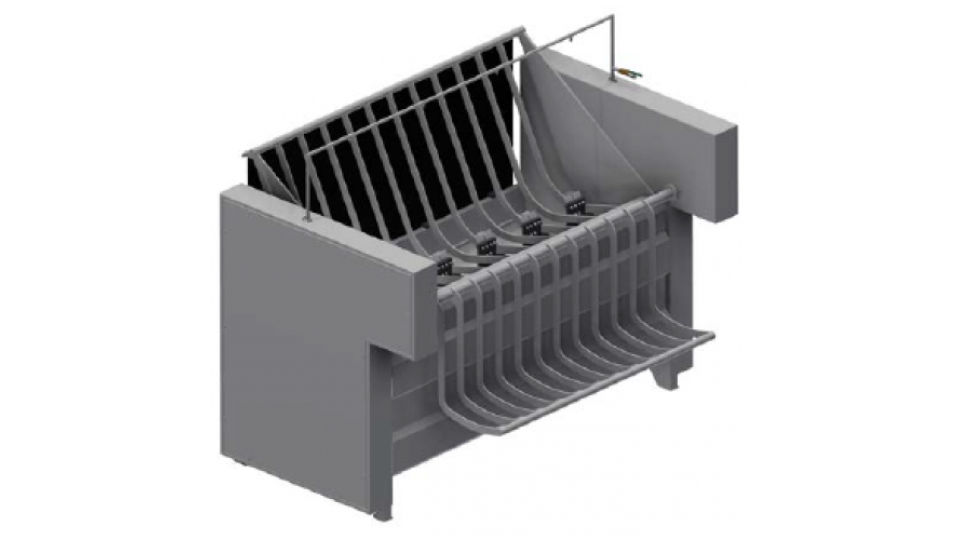

A dehairing machine is a specialized piece of equipment used in slaughterhouses and meat processing facilities to remove hair from animals, particularly pigs, during the slaughtering process. After the animals are slaughtered and scalded (a process where they are dipped in hot water to loosen the hair), they are passed through the dehairing machine. The machine uses rotating paddles or rollers equipped with blades, brushes, or rubber strips to strip the hair from the carcass quickly and efficiently.

The goal of a dehairing machine is to streamline the dehairing process, improve hygiene, and minimize the risk of contamination that can occur during manual dehairing. This machine helps to ensure that the skin of the animal is as clean as possible before further processing.

Importance of Dehairing Machines in Meat Processing

In any meat processing facility, maintaining high standards of cleanliness and efficiency is paramount. Dehairing machines play a crucial role in achieving these goals by:

- Increasing Efficiency: Manual dehairing is labor-intensive and time-consuming. A dehairing machine can process multiple animals per hour, significantly speeding up the production line and allowing for higher throughput in the slaughterhouse.

- Enhancing Hygiene: The removal of hair is essential for ensuring the cleanliness of the carcass. Hair can harbor dirt, bacteria, and other contaminants that pose a risk to food safety. Dehairing machines provide a more thorough and consistent removal of hair, reducing the likelihood of contamination.

- Reducing Labor Costs: With automated dehairing machines, there is less need for manual labor, which translates into cost savings for the processing facility. Fewer workers are required to handle the dehairing process, and the machine can operate continuously, maximizing output.

- Improving Product Quality: A clean, hair-free carcass is more appealing to consumers and easier to process in later stages. Dehairing machines ensure a smooth and uniform finish, which improves the overall quality of the final meat product.

How Dehairing Machines Work

The dehairing process typically begins after the pig or sow has been scalded. Scalding loosens the hair, making it easier to remove. The dehairing machine then completes the process using the following steps:

- Loading the Carcass: The scalded carcass is loaded into the dehairing machine. Some machines are designed for automatic loading, while others require manual placement of the carcass.

- Rotating Rollers or Paddles: The core mechanism of the dehairing machine consists of rotating rollers or paddles equipped with specialized blades or rubber strips. These rollers spin at high speeds and move in a way that scrapes the hair off the carcass without damaging the skin.

- Hair Removal: The machine effectively removes hair from all parts of the carcass, including hard-to-reach areas. Depending on the machine's design, it may use water or air to help remove loose hair and dirt during the process.

- Discharge: Once the dehairing is complete, the machine discharges the hair-free carcass, which is then ready for further processing. The hair and other waste material are typically collected for disposal or recycling.

Types of Dehairing Machines

There are various types of dehairing machines available on the market, each designed to cater to specific processing needs. Some common types include:

- Standard Dehairing Machines: These are the most common type of dehairing machine, used for processing standard-sized pigs. They come with adjustable settings to handle different sizes of pigs and are equipped with durable blades or rubber paddles to remove hair efficiently.

- Dehairing Machines for Sows: Dehairing machines for sows are specifically designed to handle larger animals such as sows and boars. Sows have thicker hair and tougher skin, so these machines are built with stronger motors and more robust paddles to ensure efficient hair removal without damaging the skin.

- Automatic Dehairing Machines: Some dehairing machines are fully automated, reducing the need for manual intervention. These machines can load, process, and discharge the carcasses automatically, increasing efficiency and allowing for continuous operation.

- Scald and Dehair Combo Machines: Some dehairing machines come with integrated scalding units, allowing for the entire process of scalding and dehairing to be done in one machine. This can save space and reduce the need for multiple pieces of equipment in smaller processing facilities.

Benefits of Using Dehairing Machines

1. Time-Saving

Dehairing machines drastically reduce the time it takes to remove hair from animals. In a manual process, dehairing a single pig can take several minutes, while a dehairing machine can process multiple pigs in the same amount of time. This makes it an essential tool for high-volume meat processing plants.

2. Consistency and Precision

Unlike manual dehairing, which can result in uneven hair removal, dehairing machines provide a consistent and uniform finish. This consistency is crucial for maintaining product quality and ensuring that all carcasses meet the same standard of cleanliness.

3. Hygiene and Safety

Dehairing machines reduce the risk of contamination by minimizing human contact with the carcass. Additionally, these machines are designed to be easy to clean and maintain, ensuring that they meet the strict hygiene standards required in the meat processing industry.

4. Cost-Effective

Although the initial investment in a dehairing machine may seem high, the long-term savings on labor costs and the increased production efficiency make it a cost-effective solution for meat processing facilities. By reducing manual labor, the machine pays for itself over time through increased productivity.

5. Improved Working Conditions

Manual dehairing is a physically demanding task that can lead to fatigue and injury over time. By automating the process, dehairing machines help to create a safer and more ergonomic working environment for employees.

Dehairing Machines in Canada

For meat processing businesses in Canada, finding reliable and high-quality dehairing machines is essential for maintaining production standards. There are several suppliers in Canada that offer dehairing machines suited to both small-scale and large-scale operations. These machines are designed to meet the specific needs of Canadian processing facilities, taking into account local regulations and market demands.

Whether you are processing pigs, sows, or other animals, it's important to choose a machine that is durable, efficient, and easy to maintain. Many Canadian suppliers offer customized solutions to meet the unique requirements of each facility, ensuring that you get the best possible equipment for your operations.

Choosing the Right Dehairing Machine

When selecting a dehairing machine for your facility, there are several factors to consider:

- Capacity: Choose a machine that can handle the volume of animals you process daily. For larger operations, a high-capacity machine is essential to keep up with demand.

- Durability: Look for a machine made from high-quality materials like stainless steel, which is resistant to corrosion and easy to clean.

- Safety Features: Ensure the machine comes with safety features such as emergency stop buttons, protective guards, and non-slip surfaces to protect operators during use.

- Ease of Maintenance: Regular maintenance is key to the longevity and performance of a dehairing machine. Choose a machine that is easy to disassemble for cleaning and servicing.

- Cost: While cost is always a factor, it's important to balance upfront costs with long-term benefits such as reduced labor expenses and increased efficiency.

Conclusion

A dehairing machine is an indispensable piece of equipment for any meat processing facility that handles pigs, sows, or other animals. By automating the dehairing process, these machines improve efficiency, enhance hygiene, and reduce labor costs. Whether you need a dehairing machine for sows or a standard model, the right machine can make a significant difference in the productivity and quality of your operations.

For businesses in Canada, investing in a high-quality dehairing machine is a smart decision that can help you meet the demands of the modern meat processing industry. With the right machine, you can ensure that your products are consistently clean, hair-free, and ready for further processing.

If you're looking to upgrade your meat processing facility, consider exploring the wide range of dehairing machines available from trusted suppliers like Presto Precision Plus, who offer advanced solutions tailored to your business needs.